Process Of Stone Crushing

2020-08-15T09:08:32+00:00

Experimental study of crushing process of the crushed

2021年2月5日 In general, crushed stone production consists of three stages: extraction of raw materials, crushing, and sorting by fractions Crushed stone is obtained quite simply by crushing various rocks, such as gravel, boulders, and various simultaneously mined 2015年9月10日 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and 11192 Crushed Stone Processing and Pulverized 2022年1月1日 Stone crushers are one of those important part of aggregate production process which convert the large size useless rocks into useful stones finding wide range Optimizing processing parameters of stone crushers through Crushing to the proper size usually occurs in stages because rapid size reduction, accomplished by applying large forces, commonly results in the production of excessive Crushed Stone an overview ScienceDirect Topics2021年5月17日 The crushing process relates to the types of crushers used in each quarry (Fig 1): cone crusher (C), impact crusher (I), quarry jaw crusher (QJ), and laboratory jaw The influence of crushing processes and mineralogy of aggregates

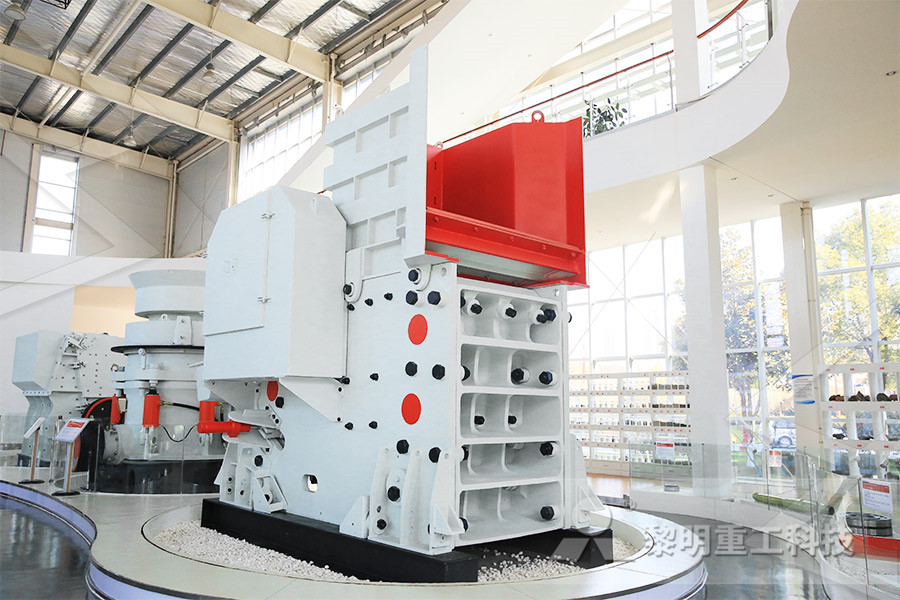

Stone Crushers: A Technical Review on Significant Part of

2022年5月13日 1 Introduction Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [1] In infrastructure industry, these 2022年5月14日 Present focus is on primary and secondary crushers used in stone crushing, because in tertiary crushing process combination of primary and secondary Stone Crushers: A Technical Review on Significant Part of2021年1月1日 The present work shows the device and principle of a laboratory centrifugal vertical impact crusher for studying the process of crushing local gravel to obtain crushed (PDF) Experimental study of crushing process of the crushed stone2020年2月8日 The crushing and grinding of stones and other particles are ruled by the laws of physics related to mass, velocity, kinetic energy, and gravity As crushing and Aggregate Production Optimization in a StoneCrushing 2020年3月1日 During the VSI crushing process, stone powder is generated in the crusher and removed through the SPS, which consists of a gassolid twophase flow Therefore, Simulation and experimental study on the stone powder

The Complete Guide to Crushed Stone and Gravel

2019年11月11日 Crushed stone often has an angular and jagged edge because of the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and 2018年9月5日 In India, the Stone Crushing Industry sector is estimated to have an annual turnover of Rs 5000 crore and is therefore an economically important sector The sector is estimated to be providing direct employment to over 500,000 people engaged in various activities such as mining, crushing plant, transportation of mined stones and crushed 1INTRODUCTION: 2PRODUCT ITS APPLICATION2017年3月4日 The process "Comminution" involves size reduction and sizewise classification called as screening or separation The objective of this report is to provide the details of size reduction methods (PDF) SIZE REDUCTION BY CRUSHING METHODS2023年10月19日 Quarrying is used mainly in the production of construction and building materials, such as solid stone or crushed rock for aggregates, or for raw materials for processes such as cement manufacture As a technique, quarrying is normally only used where raw materials of adequate quality and size cannot be obtained economically by Quarrying Process and Equipment Applications Epiroc USPublished Jan 3, 2023 + Follow A stone crushing plant typically works by crushing large stones into smaller pieces The crushed stones are then transported through a conveyor belt to a storage How does a stone crushing plant work? LinkedIn

Aggregate Production Optimization in a StoneCrushing

2020年2月8日 The stonecrushing industry plays a vital role in reducing the particle sizes of rocks and ores, and it is an important manufacturing area in rural regions involved in producing crushed stone of multiple sizes whose lack has led to a lag in actual successes of technology and has resulted in the design and process of crushing apparatus 2015年9月10日 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Some stone crushing plants produce manufactured sand This is a smallsized rock product with a maximum size of 050 11192 Crushed Stone Processing and Pulverized 2021年11月3日 Manufactured sand (MSand) is artificial sand produced from crushing hard stones into small sandsized angular shaped particles, washed and finely graded to be used as construction aggregate It is an alternative to River Sand used for construction purposes It is produced from hard granite stone by crushingManufactured Sand Process, Advantages and Types2022年4月26日 A modular framework for the implementation of optimization capabilities for crushing plants Crushing plant for aggregates production consisting of two subprocesses [Paper B] (a) SPV for varying (PDF) Optimization Capabilities for Crushing PlantsThe stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners They all work together to crush stone as efficiently as possible Conveyors connect everything, moving the crushed material from one station to the next Stone crusher plant equipment is divided into two categories:Stone Crusher Plant Setup Machinery Partner

(PDF) Stone Crushers and Dust Problem

2012年1月1日 Abstract ABSTRACT Stones are used in all the facet of life of human beings Rocks are broken into small pieces, in a stone crusher Crushing of boulders lead to production of large quantity of A stone crushing unit is composed of machines designed to reduce large stones of stone, granite, marble and lime into smaller sizes such as gravel, dust and different sizes Home; Legal assistance for any issue arising throughout the application process;How to start Stone Crushing Unit License DocumentsAlthough several authors have studied the crushing and crusher effects on the morphology and mechanical resistance of aggregates, e g [41][42][43][44][45] [46] [47][48], not many works have been Process flow sheet for the crushing tests, including 2021年6月24日 Process simulation technology The computerized “Bruno” process calculation system has already become the proven standard in the crushing industry Rock quality, feed grading and selected machines are entered to simulate the expected production capacities and product gradings Contact mineralsbruno@ accuracyfor more Crushing and Screening Handbook AusIMM2021年8月9日 Introduction and description of a stone crushing plant, complete stone crusher plant process diagram, design, installation, etc Stone crushing plant investment +86371 [ protected] NO 2, Qinling Road, Zhongyuan District, Zhengzhou, China Process of stone crushing plantStone crushing plant Henan Deya Machinery Co, Ltd

(PDF) Experimental study of crushing process of the crushed stone

2021年1月1日 To determine the optimal values of the factors affecting the process of stone crushing an algorithm flowchart has been developed and a calculation program has been compiled in Delphi As a result 2023年2月3日 The production process of stone aggregates typically involves the following steps: 1Mining or Quarrying: Extraction of raw materials (rocks, sand, gravel, etc) from natural deposits such as What is the production process of stone aggregates LinkedIn2022年12月28日 Overall, the process of operating a stone crushing quarry involves extracting the material, crushing and screening it to produce the desired final product, and sorting it into different sizes and how does a stone crushing quarry work LinkedIn2023年8月4日 The working process of stone crusher uses a machine that is designed to crush large rocks into various sizes from small, to gravel, to dust Stone crushing machines are also used to change the The Working Process Of Stone Crusher LinkedIn2020年6月9日 This study compares modelling results to measured concentrations near dust sources in a natural stone quarry and in two aggregate quarries In the natural stone quarry, the dust source was drilling and in the aggregate quarries, it was crushing Aim is to evaluate performance of model BREEZE AERMOD under 200 m from the dust source, Near field modelling of dust emissions caused by drilling and crushing

Quartz Stone: How Is It Processed and What Is It

2023年5月5日 The quartz sand production process is divided into raw quartz ore — quartz crushing — quartz sand making — quartz sand washing — quartz drying — finished products 1 Quartz crushing Jaw crusher: 2020年3月1日 Under this condition, the stone powder produced in the crushing process and from the primary material is distributed in the crushing chamber and carried into the dust storage tank Then, stone powder separation in the sandmaking process is realized A pressure transducer was used to monitor the pressure drop between the bottom and the Simulation and experimental study on the stone powder Process of Crushing Stone The procedure of crushing the stone has three stages The first stage is breaking down the stone to small sizes The second stage is crushing down the sizable stones to suit a specific purpose On the third stage, the stones are screened for finished products Sand and gravel are the most common minerals used in Process of Crushing Stone for Concrete Recycling ReAgg2023年9月14日 The most common sizes for crushed stone are: 1/4” to 3/8” 3/8” to 1/2” 1/2” to 3/4” 3/4” to 1” Crushed stone is available in a variety of colors and textures, depending on the quarry where it was sourced Some common colors include white, gray, and red Crushed stone can also be angular or rounded, depending on the shape of The Ultimate Guide to Crushed Stone and Gravel 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible Limestone crushing, sand making and grinding process

Ureteral Stones UreteroRenoscopic Stone Crushing (URS)

What is Stone Crushing (URS)? It is the process of breaking up the stones in the urinary canal (ureter) and kidney with a thin endoscope with a camera (ureterorenoscope) The procedure is performed under anesthesia (general or spinal anesthesia) and completely naturally, without any incisions in the body2013年10月4日 For the countries with a developed stone industry the waste generated in the natural stone processing plants pose environmental and economic problems The utilisation of stone waste in various areas is still under research In addition, there are only a limited number of studies concerning the use of stone waste obtained from processing Recycling waste from natural stone processing plants to stabilise 2019年3月21日 The crushing of minerals and ore is of great industrial importance With global population growth, urbanization, and continuing improvements in living conditions, the productivity and efficiency of existing crushers must be increased to meet the growing demand []Cone crushers are characterized by a continuous operating cycle and may Forces in a Cone Crusher SpringerLink2018年1月1日 The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type Modern crushing and screening production of stone materials for (PDF) Automated process control system of mobile crushing 2021年5月28日 To obtain commercial product of required quantitative and qualitative parameters, hard coal must be subjected to a number of processing operations Preliminary stone removal from runofmine is one of them Methods of such removal, including the method of selective crushing are described Design solutions for a KOMAGtype device Energies Free FullText Selective Crushing of RunofMine

Stone Crushing 911 Metallurgist

2020年10月20日 Stone Crushing Table of Contents The use of stone as a building material in relatively large blocks is recorded in ancient historical records but only within the past 200 years has broken stone in small 2004年7月1日 Granite dust is a waste material which is produced during crushing and grinding process of granite stone The annual production rate of the Maddhapara Granite Mine is 165 million metric tons from Investigations on concrete with stone crusher dust as2015年9月10日 11192 Crushed Stone Processing 111921 Process Description12 Major rock types processed by the rock and crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Some stone crushing plants produce manufactured sand This is a smallsized rock product with a maximum size of 11192 Crushed Stone Processing US EPA2022年3月7日 The process involved in crushing large size stone boulders into different size of crushed stones depending upon the requirements in the demand sectors The important stages involved in stone crushing activity are primary crushing, screening, secondary/ tertiary crusher, screening, Safety Consideration in the Development of Improved 2021年10月3日 Aggregate is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates (PDF) Production and Uses of Crushed Rock Aggregate from

Project report for Stone Crusher Unit Project report builder

The Stone Crushing Industry is a significant industrial sector in the region, manufacturing crushed stone of different sizes based on demand, which is used as a raw material in various construction activities such as the construction of roads, highways, bridges, buildings, and canals, among others Over 12,000 stone crusher units are expected 2023年10月4日 The hammer mill rock crusher can be used not only for crushing plant, sand making plant, it also can replace cone crushers in mining plant The types of stone hammers crushers: singlestage hammer crusher, highefficiency hammer crusher, sand making machine, vertical shaft hammer rock crusher, reversible hammer crusher, double Types of Stone Crushers Machine Mineral ProcessingAbstract Aggregate shape properties have a direct influence on the behaviour of pavement materials The crushing process is the main factor responsible for generating these shape properties; however, there has hardly been any effort directed toward optimising the performance of pavement materials by altering the crushing techniques to produce The influence of stone crushing processes on aggregate shape properties 2023年7月29日 The process of crushing stones for road projects is indeed an intriguing combination of art and science It involves a precise balancing act between operational efficiency, safety, environmental stewardship, and community engagement By employing the best practices and considerations highlighted herein, it’s possible to optimize Stone Crushing for Road Projects: Best Practices and 2019年11月11日 Crushed stone often has an angular and jagged edge because of the crushing process Gravel, on the other hand, typically has a very smooth texture and surface because of the natural weathering and The Complete Guide to Crushed Stone and Gravel

1INTRODUCTION: 2PRODUCT ITS APPLICATION

2018年9月5日 In India, the Stone Crushing Industry sector is estimated to have an annual turnover of Rs 5000 crore and is therefore an economically important sector The sector is estimated to be providing direct employment to over 500,000 people engaged in various activities such as mining, crushing plant, transportation of mined stones and crushed 2017年3月4日 The process "Comminution" involves size reduction and sizewise classification called as screening or separation The objective of this report is to provide the details of size reduction methods (PDF) SIZE REDUCTION BY CRUSHING METHODS2023年10月19日 Quarrying is used mainly in the production of construction and building materials, such as solid stone or crushed rock for aggregates, or for raw materials for processes such as cement manufacture As a technique, quarrying is normally only used where raw materials of adequate quality and size cannot be obtained economically by Quarrying Process and Equipment Applications Epiroc USPublished Jan 3, 2023 + Follow A stone crushing plant typically works by crushing large stones into smaller pieces The crushed stones are then transported through a conveyor belt to a storage How does a stone crushing plant work? LinkedIn2020年2月8日 The stonecrushing industry plays a vital role in reducing the particle sizes of rocks and ores, and it is an important manufacturing area in rural regions involved in producing crushed stone of multiple sizes whose lack has led to a lag in actual successes of technology and has resulted in the design and process of crushing apparatus Aggregate Production Optimization in a StoneCrushing

11192 Crushed Stone Processing and Pulverized

2015年9月10日 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Some stone crushing plants produce manufactured sand This is a smallsized rock product with a maximum size of 050 2021年11月3日 Manufactured sand (MSand) is artificial sand produced from crushing hard stones into small sandsized angular shaped particles, washed and finely graded to be used as construction aggregate It is an alternative to River Sand used for construction purposes It is produced from hard granite stone by crushingManufactured Sand Process, Advantages and Types2022年4月26日 A modular framework for the implementation of optimization capabilities for crushing plants Crushing plant for aggregates production consisting of two subprocesses [Paper B] (a) SPV for varying (PDF) Optimization Capabilities for Crushing PlantsThe stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners They all work together to crush stone as efficiently as possible Conveyors connect everything, moving the crushed material from one station to the next Stone crusher plant equipment is divided into two categories:Stone Crusher Plant Setup Machinery Partner