The Process Of Crusher Limestone

2023-05-29T05:05:17+00:00

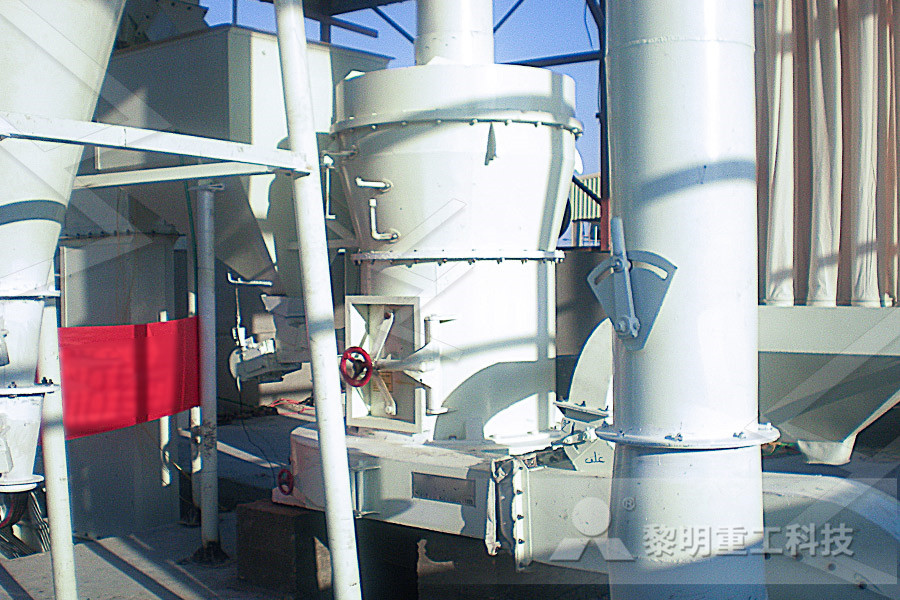

Limestone Mining Process Industrial Technology Group

2021年9月9日 Summary: The output of common limestone crushing sand making production line is 100200t/h, 200400t/h, 200500t/h, but with the largescale production, 800t/h, 1000t/h or even higher capacity sand making lines will become a trend What is 2023年2月14日 Feeding: The first step in the limestone crushing process is to feed the raw material into the crushing machine The raw material is typically fed into the machine Optimized Limestone Crushing Process for Increased 2023年9月5日 The limestone crushing production line is divided into three stages: coarse crushing, medium fine crushing and screening The first stage: coarse crushing The Limestone Aggregates Processing SHANGHAI SANME 2021年6月25日 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, 11192 Crushed Stone Processing and Pulverized 2021年2月25日 The following Luoyang Dahua expert introduces the process of processing limestone aggregate: Limestone aggregate crushing processing, it generally through Limestone Aggregate Processing Introduction Luoyang

Impact Crusher an overview ScienceDirect Topics

The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness 2021年7月15日 Energy audit for mines and miningrelated operations Metallurgical studies for mines and miningspecific processes for problems, such as lump formation, chocking Modern Technological Applications for Limestone Mining2023年1月4日 limestone crusher from Limestone can be processed using a variety of techniques Here is a flowchart outlining some of the most common processes: How is limestone processed flowchart? LinkedIn2021年10月22日 One is jaw crusher + impact crusher; The second is jaw crusher + cone crusher + vertical shaft impact crusher; The third is hammer crusher + impact crusher In Configuration and design of 1000tph limestone ZENITH Crusher2022年7月20日 Process flow of limestone crushing production line Feeding: The material is placed on the vibrating feeder by the excavator or silo, and then fed into the primary Limestone crushing, sand making and grinding process

Production European Line Association

1 天前 Learn more on each of the 4 stages in the production process: How lime is made Exploration The trucks tip the limestone into a large primary crusher which usually relies on either impact or compression to break the rock Depending on the size of the feed stone required and the kiln in which it will fed into, the same stone can go through 2023年2月15日 The limestone material discharged from a hammer crusher will be further screened to get qualified material for the next step Best crushing and equipment of Fote Manufacturer PE jaw crusher : It weighs Lime Production Process and Required Equipment 2023年3月3日 Limestone mobile crusher is a crusher that can be easily moved on the basis of fixed crusher and equipped with tire or crawler vehiclemounted device Limestone mobile crusher can be equipped with jaw crusher, cone crusher, impact crusher and other crushers to crush different raw materials and to meet the different production requirement 5 Limestone crushers make benefits to limestone plant2023年4月13日 How is the limestone process? 2Crushing: The extracted limestone is crushed to smaller sizes using a primary crusher, such as a jaw crusher, gyratory crusher, or impact crusher This reduces How is the limestone process? LinkedIn2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications However, every operator should be aware of certain do’s and don’ts when using cone crushers before making any adjustments or Do’s Don’ts Of Limestone Rock Crushing Mellott

Optimized Limestone Crushing Process for Increased

2023年2月14日 Feeding: The first step in the limestone crushing process is to feed the raw material into the crushing machine The raw material is typically fed into the machine using a vibrating feeder or a belt conveyor Primary Crushing: The next step is primary crushing, which is performed using a jaw crusher or a gyratory crusher13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The Crusher an overview ScienceDirect Topics2023年5月12日 The grain shape and gradation distribution of the roll crusher are better than that of the hammer crushers but worse than that of HVI and VSI sand crushers Hammer crusher Hammer crushers crush rocks into sand by using highspeed rotating hammerheads They are used in the primary crushing process or secondary crushing 6 Sand Making Machines and How to Choose the Best One2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible Limestone crushing, sand making and grinding process2023年3月1日 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials The crushed material is then used as an input into the Why is a crusher section used in the cement industry?

What Type of Crusher Is Best for Primary

2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, 2022年10月12日 The impact crusher is a machine with shaping sand making, uniform discharge particle size, and particle size conforming to the standard of construction sand Limestone sand making is made from the waste stone powder of the limestone stone plant, which is a waste of surplus resources, which are crushed, washed and screened by a What is a limestone crusher machine MIXING AND 2023年2月10日 crusher site Quarry crushing refers to the process of crushing and pulverizing rock to produce aggregate, which is then used in construction projects The process typically involves several What is quarry crushing LinkedIn2021年7月15日 Rippers can be used for limestone mining as limestone is a ‘rippable’ sedimentary rock (refer to Sect 311) Using rippers in small mines or for a group consisting of more than one mine is economical and productive Instantaneous blasting or blasting with delay detonators in mines are executed in circuitsModern Technological Applications for Limestone Mining2023年2月28日 The processing of limestone ore typically involves extraction, crushing, grinding, and calcination Extraction refers to the process of removing the limestone from the earth's surface or How limestone ore is processed? LinkedIn

Crusher RQHUXVKHU IOPscience

2022年2月18日 Abstract Crushing is the process of reducing the size of ore into definite smaller sizes Cone crusher is a size reduction mechanical equipment which crushes the large sized limestone and dolomite particles by squeezing it between gyrating spindles Crusher must be mounted on a frame to be coupled with the motor drive2020年2月18日 23 Limestone Mining Process: A Brief Review The sum total of all activities that are undertaken during the lifetime of a mine can be categorized The extracted ore is hauled to the surface and subsequently transported using trucks or dumpers to the crusher, where the ore is converted into smaller pieces This is followed by Environmental Hazards of Limestone Mining and Adaptive2023年2月16日 Calcium chloride can be extracted from limestone through a multistep process involving heating, evaporation, and chemical reactions Here is a general outline of the process: 1Obtain limestone How to extract calcium chloride from limestone LinkedIn2019年11月4日 The crushed limestone is uniformly conveyed to the cone crusher or impact crusher by the conveyor belt for medium and fine crushing After crushing, it is screened by a circular vibrating screen The largergrained limestone is returned to the cone crusher and crushed again; the mediumsized limestone is sent to the next processLimestone Rock Crushing Flow Price JXSC Machine2023年3月30日 crusher The process of mining iron ore involves drilling, blasting, hauling, crushing and screening First, holes are drilled into the rock surface using large machines Then, explosives What is the process of mining iron ore? LinkedIn

Everything you need to know about Crushers in Cement

The roller crushers are used for moist and sticky materials Generally the machines have to be rigid enough to crush also hard inclusions As the reduction ratio is only about 5:1 a 2stage crushing is required in most applications Fast running type crushers like hammer and impact crushers are the simplest and cheapest solution, whenever the 2021年2月25日 The following Luoyang Dahua expert introduces the process of processing limestone aggregate: Limestone aggregate crushing processing, it generally through crushing, screening and washing, to make aggregates that conform to the grading The production of limestone aggregate needs to design a complete processing systemLimestone Aggregate Processing Introduction Luoyang 2019年9月28日 Jaw crusher machine is the most popular primary crusher and it is applicable for almost every kind of stone materials Its feeding size is higher than 1500mm and discharging size is in the scope of 10mm and 350mm With features of high working efficiency, simple structure and easy maintenance, jaw crushing machine price of FTM What type of rock is limestone? FTM Machinery2019年10月8日 Limestone is a common nonmetallic mineral, which is also a trading name as a raw material mineral Limestone is widely used because of its wide distribution and easy access in nature There are several types of rock crusher machine can process limestones, such as fixed jaw crusher, impact rock crusher machine, hammer crusher How to Process Limestone? Blog HongXing Machinery2023年3月13日 Here's a general overview of the process: 1Crushing: The raw limestone is first crushed by a jaw crusher or a hammer crusher to a size of about 2040mm 2Grinding: The crushed limestone is then How the limestone grinding line is processed? LinkedIn

Limestone Crusher: An Edge Tool for Making Crushed Limestone

2023年7月11日 When crushing limestone with a mud content of less than 5% and a moisture content of less than 7%, choose a hammer crusher Hammer crushers are the first choice for crushing soft to mediumhard rocks Moreover, with small crushing cavity and wellsealed structure, hammer crushers solve the problems of dust pollution and powder 2020年10月20日 Crushed stone is produced from all three groups of rocks on the earth’s surface—igneous, sedimentary, and metamorphic It has been estimated that the lithosphere, the solid portion of the earth’s crust, is composed of: igneous rocks, 95 pct; shale, 4 pct; sandstone, 075 pct; limestone, 025 pct However, these percentages by no Stone Crushing 911 MetallurgistThe impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness Effect of process conditions on the production capacity of crushed materials is Impact Crusher an overview ScienceDirect TopicsFor the sedimentary rocks (Siltstone) the specific crushing energy is approximately 126 kJ/kg Tosun and Konak (2014) measured power consumption of jaw crusher during crushing of limestone rocks Table 6 Energy consumption values of each crusher per tonne2023年3月3日 Limestone impact crusher The limestone impact crusher organically combines the crushing principles of strike, impact, centrifugal impact, shearing and grinding, so as to make full and effective use of its energy and crushing cavity Feeding size: 01300mm Capacity: max to 2100t/h5 Limestone crushers make benefits to limestone plant

11192 Crushed Stone Processing and Pulverized

2015年9月10日 111921 Process Description 24, 25 Crushed Stone Processing Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, crusher product, normally 75 to 30 centimeters (3 to 12 inches) in diameter, and the grizzly 2020年9月16日 A jaw crusher is a type of crusher comprised of two jaw plates One is a fixed jaw plate that is vertically fixed on the antetheca of the body, and another is a moving jaw plate, forming a Five Types of Crusher in the Mineral Processing LinkedInPublished Dec 29, 2022 + Follow Limestone crushers work by applying pressure to the material to reduce it in size There are several types of limestone crushers, including: 1Jaw crushers: Jaw How the limestone crusher works LinkedIn1 天前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types 2 Secondary CrushingTypes of Rock Crushers Quarry Crushing Equipment Kemper2019年6月28日 Introduction Crushers play an important role in the material handling process for underground mine operations The main purpose of a crusher is the size reduction of the feed This size reduction is achieved by applying a force to the material, creating cracks in the material which in the end will cause the material to break into Crushers QueensMineDesignWiki

Jaypee Group Businesses CementManufacturing Process

2023年6月21日 The cement manufacturing process starts from the mining of limestone, which is the main raw material for making cement Limestone is excavated from open cast mines after drilling and blasting and loaded on to dumpers which transport the material and unload into hoppers of the limestone crushers Crushing Stacking Reclaiming of 2021年4月19日 Herein, we evaluate experimentally the interactions among clinker, limestone and gypsum during the final grinding stage in Portland cement production We present a simple, yet rigorous, method that enables the determination of the individual grinding contributions to the intergrinding process By using Rittinger’s KR parameter, our Resistance to Grinding and Cement Paste Performance of 2023年2月15日 2Labor cost: The cost of labor involved in the crushing process, such as wages for operators and maintenance personnel 3Material cost: The cost of the limestone itself, which can vary depending What is the cost of limestone crushing process LinkedIn2023年3月1日 Crushing: The extracted limestone is then crushed into smaller pieces using a crusher or a hammer mill This process reduces the size of the limestone to a more manageable size for further processinghow is limestone processed from a raw material to a final1 天前 Learn more on each of the 4 stages in the production process: How lime is made Exploration The trucks tip the limestone into a large primary crusher which usually relies on either impact or compression to break the rock Depending on the size of the feed stone required and the kiln in which it will fed into, the same stone can go through Production European Line Association

Lime Production Process and Required Equipment

2023年2月15日 The limestone material discharged from a hammer crusher will be further screened to get qualified material for the next step Best crushing and equipment of Fote Manufacturer PE jaw crusher : It weighs 2023年3月3日 Limestone mobile crusher is a crusher that can be easily moved on the basis of fixed crusher and equipped with tire or crawler vehiclemounted device Limestone mobile crusher can be equipped with jaw crusher, cone crusher, impact crusher and other crushers to crush different raw materials and to meet the different production requirement 5 Limestone crushers make benefits to limestone plant2023年4月13日 How is the limestone process? 2Crushing: The extracted limestone is crushed to smaller sizes using a primary crusher, such as a jaw crusher, gyratory crusher, or impact crusher This reduces How is the limestone process? LinkedIn2023年3月27日 Limestone crushing is an essential part of the mining and construction industry Cone crusher parts are used for this purpose, and they come in various sizes and configurations to match different applications However, every operator should be aware of certain do’s and don’ts when using cone crushers before making any adjustments or Do’s Don’ts Of Limestone Rock Crushing Mellott2023年2月14日 Feeding: The first step in the limestone crushing process is to feed the raw material into the crushing machine The raw material is typically fed into the machine using a vibrating feeder or a belt conveyor Primary Crushing: The next step is primary crushing, which is performed using a jaw crusher or a gyratory crusherOptimized Limestone Crushing Process for Increased

Crusher an overview ScienceDirect Topics

13311 Primary Crusher Primary crushers are heavyduty rugged machines used to crush ROM ore of (−) 15 m size These largesized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm The 2023年5月12日 The grain shape and gradation distribution of the roll crusher are better than that of the hammer crushers but worse than that of HVI and VSI sand crushers Hammer crusher Hammer crushers crush rocks into sand by using highspeed rotating hammerheads They are used in the primary crushing process or secondary crushing 6 Sand Making Machines and How to Choose the Best One2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible Limestone crushing, sand making and grinding process2023年3月1日 A crusher section is used in the cement industry to reduce the size of raw materials such as limestone, clay, and other materials The crushed material is then used as an input into the Why is a crusher section used in the cement industry?